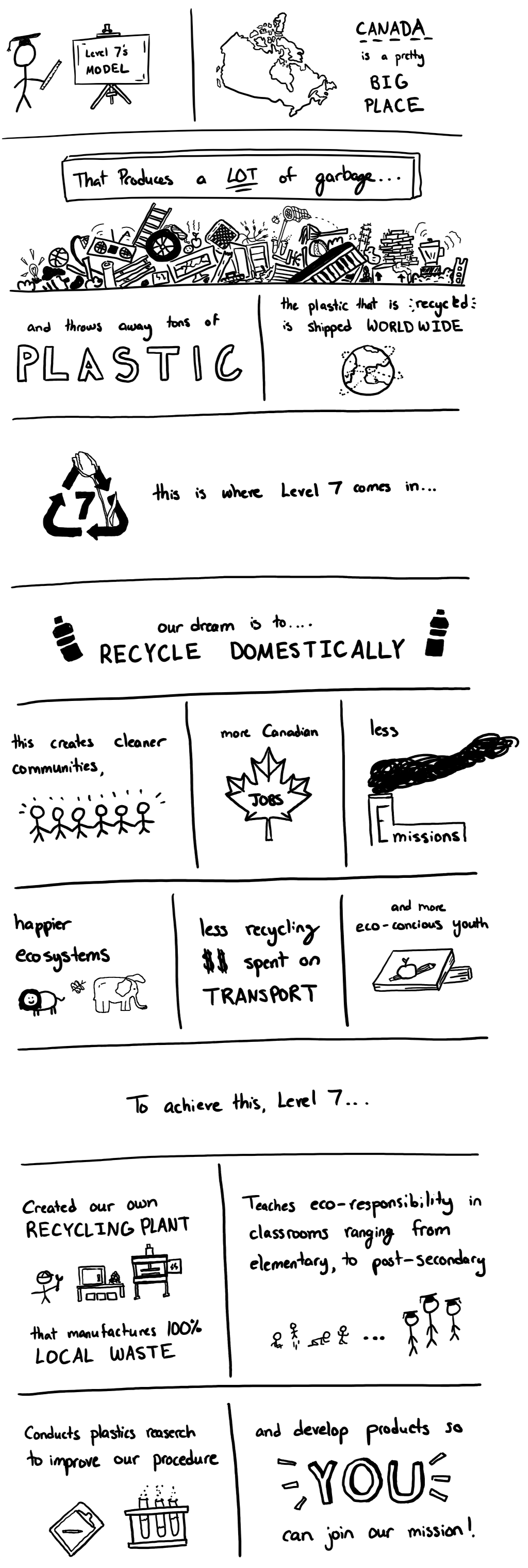

Plastic Waste is a Global Concern

This section elaborates on how much plastic is consumed and recycled on an annual basis.

China Has Closed its Doors

This section describes North America’s recycling dependencies, specifically outlining the plastic waste trade since 2017.

The Cost of Shipping Plastic

This section depicts the route many North American plastics travel after they are placed in the blue bin.

Plastic is Everywhere

This section describes the numerous uses and industrial benefits plastics provide while also predicting their long-term use.

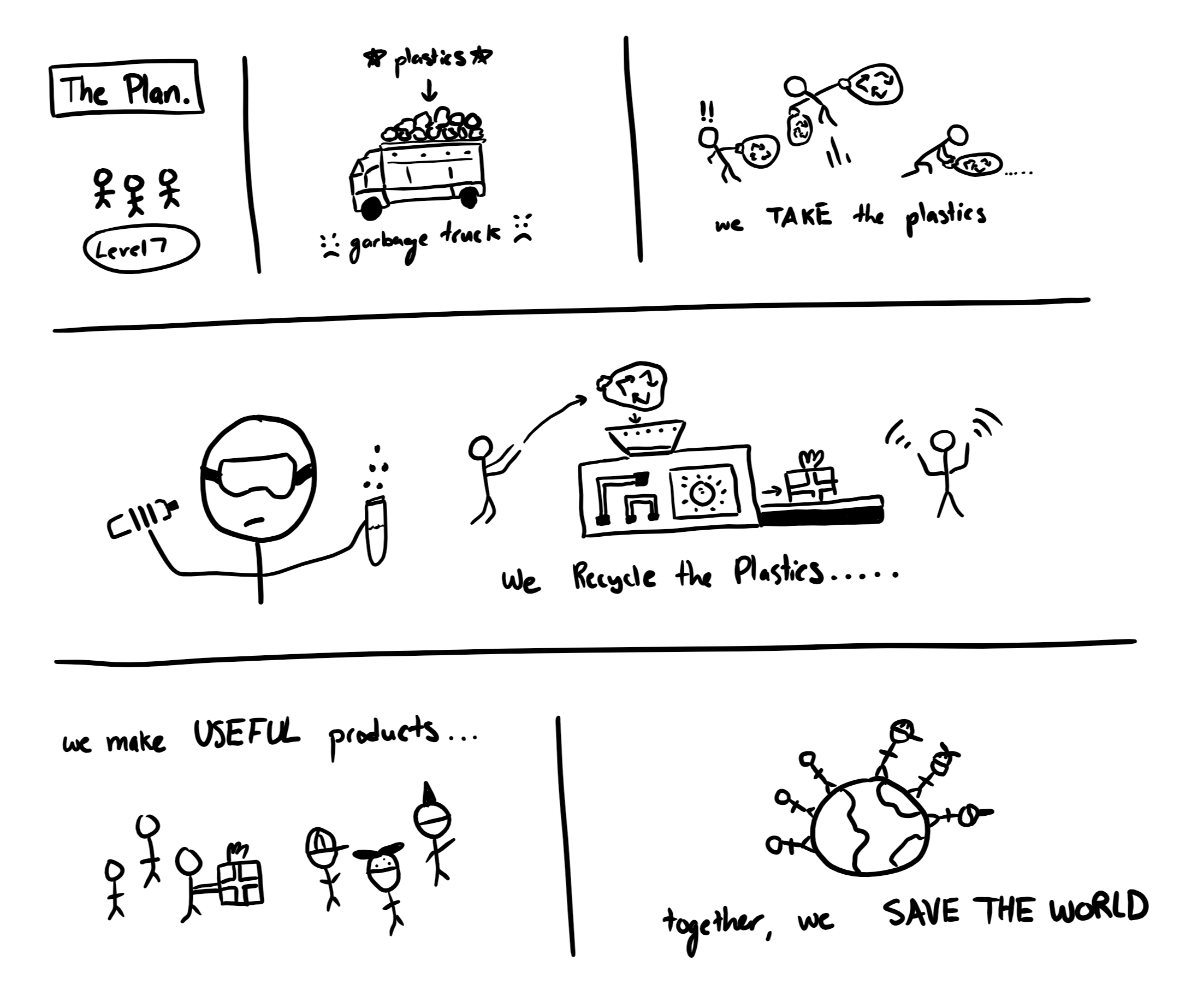

Where does Level 7 fit in the Canadian recycling industry?

Recycling beyond the blue bag.

Learn how Level 7 produces useful items using recyclable thermoplastics.

Step #1: Collecting and Sorting

How We Collect Plastic

Currently, Level 7 obtains 500kg bales of plastic from the Edmonton Waste Management Center. These bales of plastic contain recyclable waste that has been collected from homes, businesses, public locations, etc. By collecting plastic from our city directly, we are able to maximize our outreach to many facets in the local community.

Types of Plastic We Recycle

For the time being, Level 7 is restricted to recycling thermoplastics that are not hygroscopic; plastics that do not absorb moisture from their surroundings. As a result, HDPE and PP are Level 7’s two most recycled plastics. These plastics are commonly found in shampoo bottles, laundry detergent bottles, and cleaning products.

Hygroscopic materials, such as PET, are not yet recycled by Level 7 due to their polymer structure containing water molecules. Water present in the plastic’s molecular structure will inevitably create issues for heat-based machining as well as compromising the plastic’s properties. Level 7 is moving to incorporate hygroscopic materials in its recycling procedure.

Colour Distributions and Rarity

The following graph provides a visual representation of the plastic waste Level 7 typically has available.

Step #2: Granulating

The Purpose of Shredding

Bottles, plastic toys, and containers all occupy a large amount of volume relative to the mass they possess. For this reason, plastic is shredded into small flakes that occupy little space and are significantly more manageable to process and manufacture. Furthermore, the flakes also allows for more thorough cleaning in the washing and drying steps.

How We Shred

The shredder shown above is responsible for granulating plastic waste into small, manageable pieces. The machine is laser cut, made of cold-worked steel, and features a motor with more torque than a car. This shredder is capable of decimating a mass equivalent of over 1000 plastic bottles per day.

Step #3: Washing and Drying

Substances Removed During Washing

Plastics are used in a massive variety of applications. As a result, they are often contaminated with additional substances, ranging from dirt to laundry detergent. This cannot be present in our products. Our plastic is power washed at high pressure and temperature with chemical disinfectant to remove any trace of contaminants. Afterwards, the plastic is soaked and rinsed in water to ensure there is no residual soap.

Drying is Important

Drying is a crucial yet often overlooked step in the recycling process. To explain why, the difference between a ‘hygroscopic’ and ‘non-hygroscopic’ plastics must be defined first. A hygroscopic material absorbs water into its molecular structure, while a non-hygroscopic material does not. Plastics fall into both categories: HDPE in milk jugs is non-hydroscopic, while PET in water bottles is.

Level 7 is currently focused on non-hygroscopic plastics. While this simplifies our procedure by removing atomic impurities, surface moisture must still be removed. Wet plastic is harmful because the steam generated in the melting steps can damage machinery and the materials structural stability. To inhibit this, we first subject our plastics to a ‘pre-bake’ to remove the majority of the water, then allow it to rest in open air for 72 hours.

Although Level 7 does not yet recycle hygroscopic materials, we plan to in the future as our manufacturing develops.

Step #4: Melting

The Art of the Sheet Press

The sheet press combines extreme heat and pressure to create a plastic block of precise dimension, strength, and long-lasting durability. Our sheet press design utilizes the toughness of steel, the thermal conductivity of aluminum, and the insulation of Teflon to guarantee our plastic is of high quality and thermal efficiency, as shown in the graphic above. The produced blocks of plastic are typically sent to a CNC to be manufactured into the desired product.

Injection Molding

There is a reason injection molding is perhaps the most often used manufacturing method for thermoplastics. Injection molding is capable of creating objects of extreme geometric complexity, producing thousands or even millions of products quickly, and is very reliable in color accuracy, durability, and strength. Level 7 partners with existing companies or organizations that utilize injection molding. In addition, Level 7 is developing its own injection molder that is especially suited for our products.

Plastic Welding

Plastic welding is a manufacturing technique seen in the automotive industry, packaging applications, and the medical industry. These massive fields utilize plastic welding for its extreme strength and durability, precision, and ease of use. Level 7 relies on this technology for the same reasons, but for fusing desk diaphragms, tile grid patterns, and storage containers.

Step #5: Manufacturing

Methods of Manufacturing

Level 7 relies on many manufacturing methods for specific applications or designs, namely:

CNC Machining:

‘Computer Numerical Control’ machining is a subtractive manufacturing technique Level 7 uses to shape plastic blocks into designs with contours. This machine uses an automated computer-led router in tandem with a special spindle bit to remove material from a stock body — creating objects precisely and consistently.

FDM 3D Printing:

‘Fused Deposition Modelling’ 3D printers act opposite of a CNC; they add material to create an object rather then remove it. Level 7 utilizes 3D printers for designs of extreme complexity and minimal strength requirements.

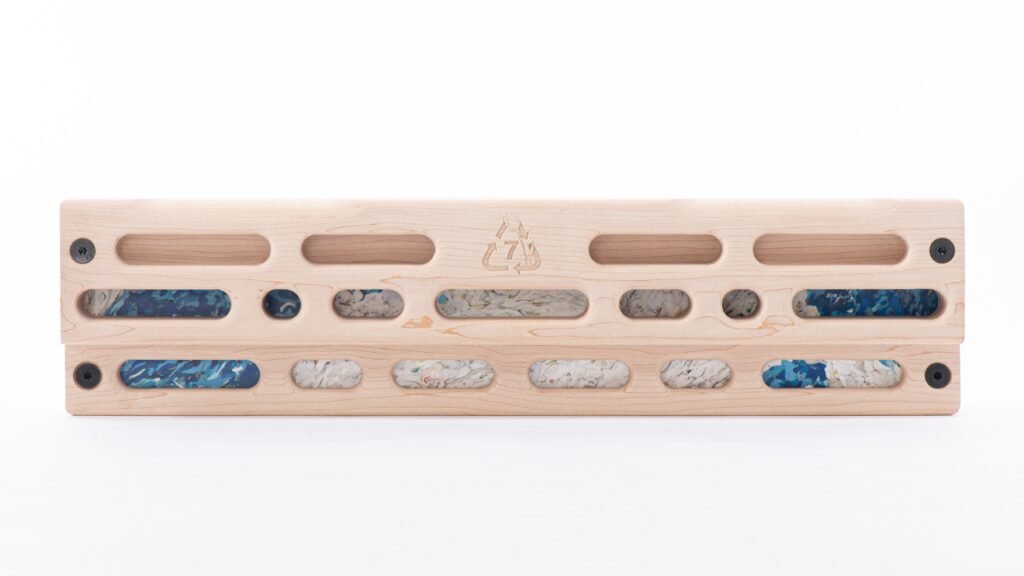

Benefits of Composite Products

Composite designs are nothing new to engineering. For example, a large bridge is typically made of both concrete and steel. Concrete has fantastic compressive properties but behaves very poorly under tension. Steel is used in the locations of high tension in order to utilize each material’s strengths in a cost-effective manner. Composite products commonly operate with this methodology, whether it is from an engineering standpoint or simply for aesthetics.

The same mindset is used in Level 7 products. An example of this is our hangboard, which relies on a recycled HDPE backing for resisting shear stress, and a wood face to provide a comfortable texture for the user’s fingertips.

Learn about our plastics.

Subjects include: plastic’s fantastic properties and Level 7’s manufacturing methodology.

Learn about our products.

Subjects include: the Chalkboard, the Perfectionist’s Study, the Tile, and the Wave.